Navin’s Sets a New Benchmark as Chennai’s First Real Estate Developer to Implement 3D Concrete Printing

Date : 2026-02-20

What if your next home was partly built using robotic precision with millimetre-level accuracy, minimal material waste, and design forms that were previously difficult to achieve? That is no longer a future concept. It is already happening at Navin's Starwoods Towers 3.0, where Navin's Housing has become the first real estate developer to implement 3D concrete printing in Chennai within a residential project.

This milestone is not an innovation for publicity. It is a carefully engineered step towards smarter construction practices that signal where the city’s real estate market is heading.

As demand grows for premium and luxury apartments in Chennai in 2025, technology-driven construction methods are becoming increasingly important to deliver better quality, efficiency, and design flexibility.

What Is 3D Concrete Printing and Why It Matters for Homebuyers

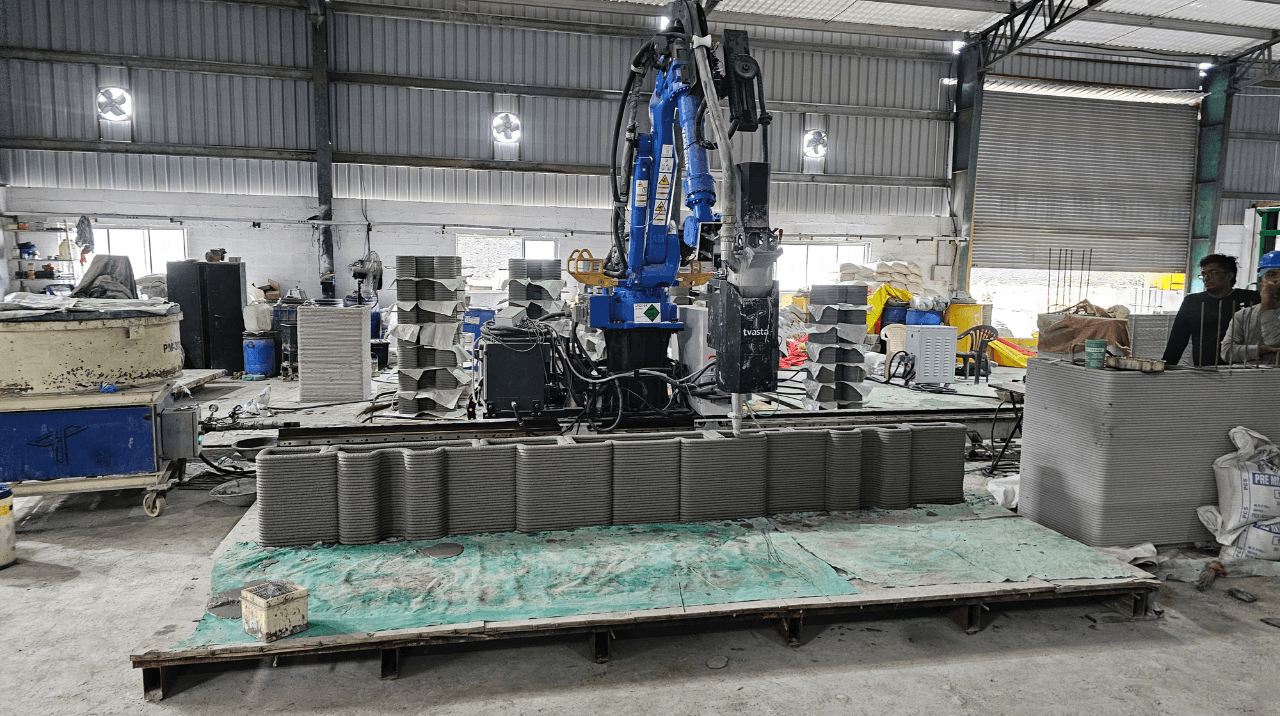

3D concrete printing is a robotic construction process that deposits concrete layer by layer based on a precise digital design. It removes the need for traditional formwork and reduces heavy manual labour dependency.

In simple terms, it works like a large-scale architectural printer where a robotic arm follows a computer-generated model and builds structures with high accuracy.

The four-step process includes:

- Digital Design

Architects create a detailed 3D model using specialized CAD software. - Material Preparation

A specially engineered concrete mix is developed for strength, durability, and controlled flow. - Automated Printing

A robotic system deposits concrete layer by layer according to the digital plan. - Setting and Finishing

The printed structure hardens, and finishing work is completed where required.

For homebuyers, this translates into:

- Better quality control

- Greater design freedom

- Faster construction timelines

- Reduced material wastage

- Improved structural consistency

These benefits directly influence the long term durability and reliability of homes.

Is 3D Concrete Printing Safe and Structurally Reliable?

A natural concern among buyers is whether 3D-printed homes in India are safe and proven.

The answer is yes when executed correctly.

Globally, this technology has already been used across:

- Residential housing projects

- Bridge construction

- Public infrastructure

- Commercial buildings

Concrete mixes are engineered to meet structural requirements, and construction follows established engineering codes and safety regulations.

Regarding earthquake resistance, performance depends on structural engineering design and reinforcement planning rather than the construction method itself. When aligned with Indian seismic codes such as IS 1893, printed components can perform effectively in seismic conditions.

How Navin’s Implemented 3D Concrete Printing at Navin’s Starwoods Towers 3.0

At Navin’s Starwoods Towers 3.0, 3D concrete printing has been strategically introduced within the landscaped podium, which serves as a vibrant communal space where residents gather, relax, and interact.

The primary structural system of the project uses Mivan construction technology for efficiency and speed. The 3D printing intervention was applied in non-structural zones where complex architectural forms were required.

Key printed elements include:

- Organic curved seating areas with sculptural forms

- A parametric feature wall integrated with a waterfall

- Custom-designed architectural features enhancing user interaction

Executing these geometries using conventional construction would have required:

- Complex customized formwork

- Highly skilled labour

- Continuous supervision

- Repeated setup and dismantling cycles

By using 3D concrete printing, Navin’s avoided the need for complex customised formwork, which could have increased costs by three to five times compared to standard construction.

Navin’s partnered with Tvasta, an IIT Madras-incubated construction technology company specialising in digital construction solutions, to execute these components directly from digital models with high precision.

Up to Five Times Faster Than Traditional Construction

Speed is one of the most compelling advantages of 3D concrete printing.

In traditional construction, creating curved or complex elements requires multiple stages, including formwork fabrication, installation, concrete pouring, curing, and removal before the next section begins.

With 3D printing technology:

- Execution time can be reduced by up to five times

- Formwork dependency is significantly reduced

- Material wastage is minimized

- Labour intensity drops for complex elements

- Precision improves as designs are reproduced exactly

This leads to faster project delivery and better resource efficiency.

Cost Efficiency: Does Advanced Technology Increase Prices?

Advanced technology may appear expensive initially, but the cost equation is more nuanced.

For standard straight line construction, traditional methods remain economical. However, for complex architectural geometries, digital printing can actually reduce costs by eliminating expensive custom formwork, reducing labour stages, and shortening timelines.

At Navin’s Starwoods Towers 3.0, 3D printing was applied specifically where it delivered maximum value. This targeted implementation resulted in:

- Optimized material usage

- Reduced wastage

- More predictable timelines

- Better cost control for specialized elements

When Form Becomes Fluid: A New Design Experience

Architectural forms that were once technically difficult or expensive to achieve can now be executed more easily.

At Navin’s Starwoods Towers 3.0, the podium is not just a shared space. It is an experiential environment where every curve and surface has been executed exactly as designed.

When form becomes fluid, space becomes experiential.

Technology has transformed a functional area into a visually engaging and memorable place for residents.

Navin’s and Construction 4.0 India

By adopting 3D concrete printing, Navin’s is aligning with the global movement of Construction 4.0 India, which integrates automation, robotics, and digital engineering into building processes.

This initiative demonstrates:

- Innovation applied with a clear purpose

- Efficient use of construction resources

- Future-ready development practices

- Improved residential experiences beyond amenities

It also positions Navin’s among forward-thinking developers shaping the future of urban housing.

The Future of 3D Printed Homes in India

India is still at an early stage of adopting digital construction technology, but the potential is significant.

In the coming years, 3D printing could transform:

- Affordable housing delivery

- Mid-segment residential projects

- Architectural customisation

- Sustainable construction practices

- Urban infrastructure development

As cities like Chennai continue to expand, faster and smarter construction methods will become essential to meet housing demand without compromising quality.

Navin’s early adoption of Navin’s Starwoods Towers 3.0 demonstrates that advanced construction technologies are not just experimental concepts. They are practical, scalable, and ready for real-world residential applications today.